I-PULSE S10-M10, S20-M20

Call us

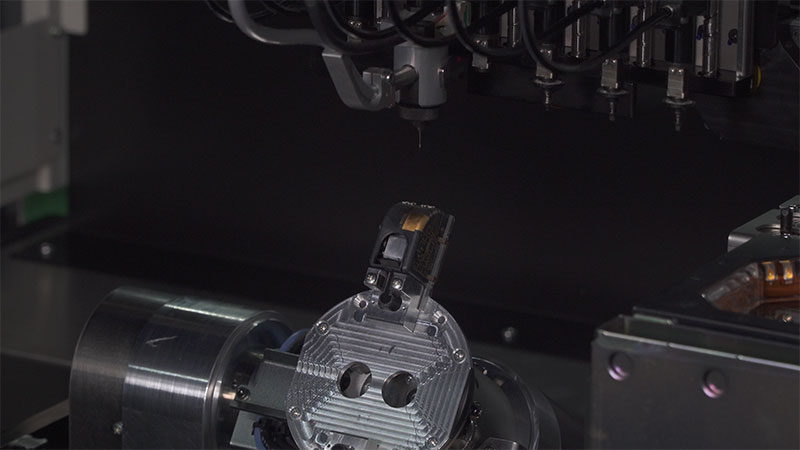

Ultimate Flexibility to realize 3D MID* Placement

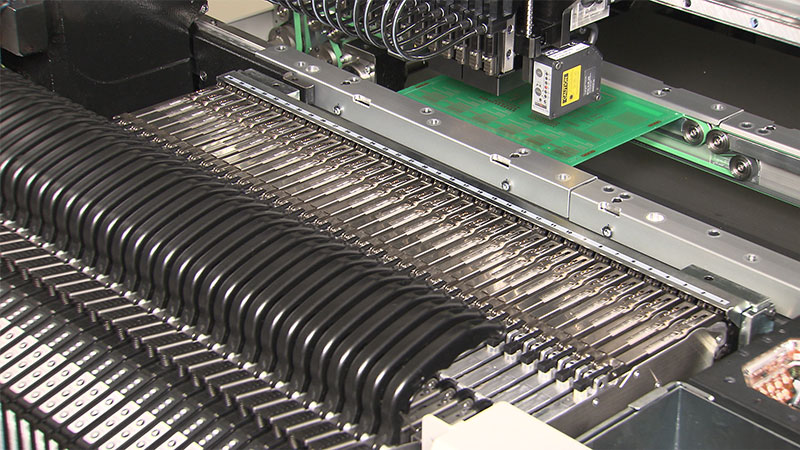

- Enhancement to 3D MID

- Large board handling capability

- Wide ranging component handling capability and high feeder capacity

- Ultimate flexibility and fast & easy setup

- * 3D MID: MOLDED INTERCONNECT DEVICE

Hotline: +84 988 919 818

+84 769 116 968

Email: cuong@smt-vn.com

sales@smt-vn.com

* Function and Feature

Realize a hybrid process of mount and dispensing

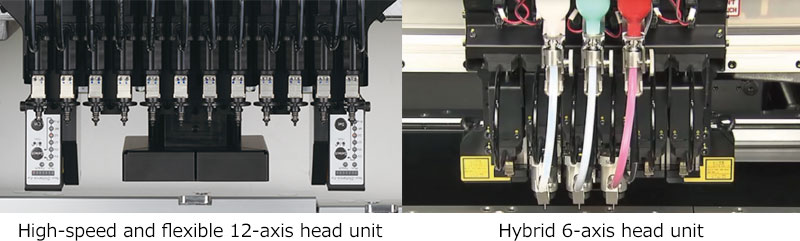

New head unit for higher speed placement

Long board handling capability

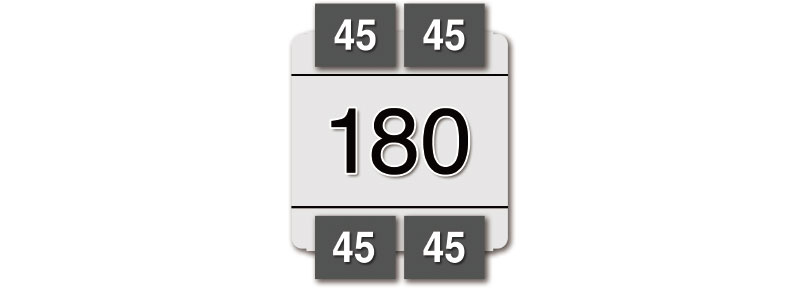

Max. feeder capacity 180 lanes

* Recommend for Such Production Site

For customers who want a cost-effective yet super-flexible machine

Even though an entry model, it has high flexibility, basic functions and also proves an ideal multi-purpose machine for high-speed lines.

1. Achieves superior conveyor performance with enhanced PCB handling Multi-Conveyor System.

- Handles PCBs from L50xW30xT0.4mm to L955(S10)/L1,455(S20)xW510xT5.0mm with 4kg weight as standard feature (can handle 20kg or more by special order).

- Input and output buffer conveyor system is standard equipment, and auto selection of optimal conveyor settings is made according to PCB size.

- Laser sensor on head unit eliminates need for mechanical PCB stoppers. Automatically provides optimal PCB position regardless of size or shape even for cut-out PCBs.

2. Standard specifications allow handling nearly all component recognition processes.

- Handles from 0402mm to 120x90mm components with a standard camera (OP 0201mm onwards). Can place any component without having to worry about its specifications.

- Rear multi-scan camera (OP) ensures highly efficient component placement

3.Feeder banks can be freely arranged to match needs

- Maximum feeder capacity of 90 types (S10)/180 types (S20) + simultaneously accommodates two (S10)/four (S20) JEDEC tray types. (when all 45-lane feeder banks+RTS-1 are selected. During 8mm tape feeder conversion)

- Full range of retrofit kits allows changing from fixed feeder banks to feeder carriages/tray feeders; or feeder carriages/tray feeders to fixed feeder banks.

- Allows freely selecting different front/rear and left/right bank configurations according to production needs and budget.

- The CTF-36C can dock with each of the M10/M20 and S10/S20 in the same way as the CFB-36E/CFB-45E.

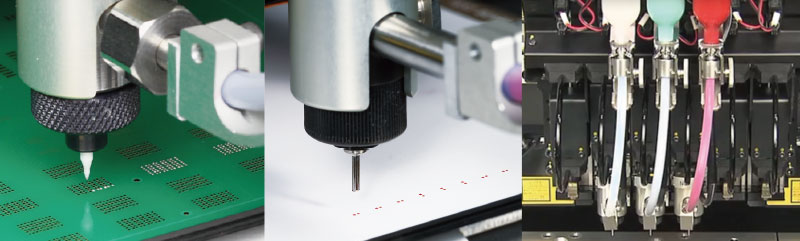

4. High-speed multi-purpose head and hybrid head meet a wide range of production needs.

- Can handle component heights up to 30mm Remark : Conveyor surface reference including PCB thickness

- Real-time force control function as standard feature, also capable of reducing stress on components and handling component insertion.

- PCB warp detection function as standard, automatic control of component release height during placement

- Wide FOV fiducial camera comes as a standard feature, capable of work recognition via optimal color element according to the work piece (fiducial marks and mounted components).

- One dispenser head (OP) can be installed per placement nozzle as needed as a hybrid head for repetitive hybrid dispensing and mounting processes.

- For customers who want to look at SMT line dedicated to R & D production

* For customers who want to look at SMT line dedicated to R & D production

1. Reduces the setup/changeover time.

- Maximum feeder capacity of 90 types (S10)/180 types (S20) + simultaneously accommodates two (S10)/four (S20) JEDEC tray types. (when all 45-lane feeder banks+RTS-1 are selected. During 8mm tape feeder conversion)

- Easy exchange to/from tray changer (CTF-36C) to/from the feeder carriage (CFB-36E/CFB-45E)

- Auto Nozzle Changer (ANC) with 24 holes available comes as a standard feature, and also ANC with 40 holes available as option to support further a wide range of components.

- Effective for prototype PCBs and high-mix low-volume production. Relocatability function (OP of Intelligent Feeder) for feeders and trays eliminates need for component supply position management.

2. Superb all-in-one functions make it usable as a single stand-alone machine

- Maximum feeder capacity of 90 types (S10)/180 types (S20) + simultaneously accommodates two (S10)/four (S20) JEDEC tray types. (when all 45-lane feeder banks+RTS-1 are selected. During 8mm tape feeder conversion)

- A wide range of components from 0402mm (OP 0201mm onwards) to 120x90mmxT30mm* can be handled as standard. Remark : Conveyor surface reference including PCB thickness

- Real-time force control function as standard feature, also capable of reducing stress on components and handling component insertion.

- PCB warp detection function as standard, automatic control of component release height during placement

- Auto Nozzle Changer (ANC) with 24 holes available as standard equipment, and also ANC with 40 holes as a option. Ideal for handling a variety of component types while changing nozzles

3. Various functions make it simple to create data

- iQvision(OP): Recognizes super-wide odd-shaped components that are difficult to handle by standard recognition.

- Wide FOV color FID camera: Reliable recognition of mounted components

- Data creation support function for tray component pickup position with multiple-image capture around the center

- Dispensing program: This can be created by batch conversion from placement program – Can be managed as single program with same cycle as placement program

4. Supports cost-cutting for prototype products.

- Auto-generation of dispensing program from Gerber data for metal stencils. This eliminates the cost of making metal stencils with dispensing-printing functions and that therefore do not need metal stencils.

- Dispensed dot inspection function (special order) that guarantees the quality of the dispensing function

- Handles a wide range of stick components; Simple general-purpose stick component tracks are supplied as standard accessories for the stick feeder.

* For customers who want to manufacture LED lighting PCBs

Dozens of functions allow manufacturing high-quality LED lighting PCBs at a low investment

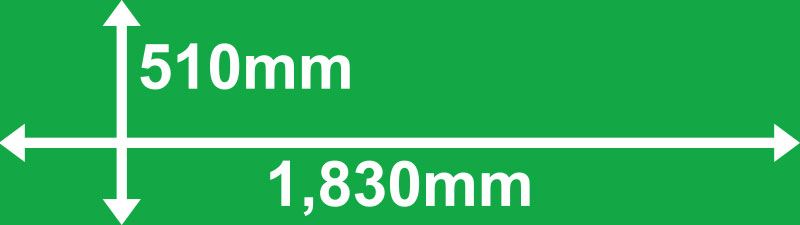

1. Handles long size and heavy-weight PCBs.

- Handles PCB lengths up to L1,330m(S10)/1,830mm(S20) as option; comes with warped PCB transfer guide function that prevents transfer errors at conveyor entrance.

- Capable of handling PCB weight 4kg (standard) and 20kg or more (special orders) even including a PCB carrier.

- Rigid PCB supporting by double-sided clamping of top side and bottom side PCB edge surface

- Laser sensor on head unit eliminates need for mechanical PCB stoppers. Cut-out PCBs can be freely positioned at a desired point with the PCB edge setting. No impact stopping needed even for heavy PCBs.

2. Handles a variety of LED components with freely configurable feeder bank.

- Interface kit is available (standard OP) that allows connecting to feeders (ball feeders, etc.) made by other manufacturers.

- A full range of retrofit kits allowing changing the feeder bank layout

3. Heads and nozzles ideal for LED chip placement are selectable.

- Select from high-speed multi-purpose heads for mounting LED chips, and hybrid heads ideal for mounting LED lens covers.

- Laser PCB warp detection comes as a standard feature, automatic controlling of component release height during placement even for warped PCBs

- A wide FOV fiducial camera as standard feature, capable of work recognition with optimal color element according to work piece(fiducial marks and placed components).

- A wide range of semi-standard LED nozzles are available for mounting LED chips having a variety of shapes.

4. Equipped with functions to support high-quality LED lighting PCB production

- LED rank management function allows setting placement by rank condition (special order).

- Adhesive dispensing program for hybrid dispenser functions can be automatically generated by batch conversion from component placement programs.

* Hybrid production processes

True super-flexibility with everything the user “wants” clustered into a single unit that allows running the following processes

1. Hybrid dispenser function that carries out mounting and dispensing in a single cycle

- A maximum of 4 dispense heads can be installed.

- Mixed head configuration for mounting and dispensing allows running the dispensing->mounting-> dispensing-> mounting processes on a single unit.

- Utilizes a non-contact dispensing system and line dispensing function as a standard feature.

- Screw pump type dispenser: For high-speed micro-dot dispensing providing fine dispensing-volume control

- Air pulse type dispenser: For general-purpose dispensing that handles a wide range of dispensing materials and dot sizes

2. Mounting functions for hybrid processes

- Maximum 30mm height (component + PCB) can be achieved with the hybrid head which is also ideal for POP processes with height requirements.

- Hybrid heads with 30mm head pitch do not bind or interfere with each other even during line dispensing and large-size shield cover mounting in the same process.

3. Various types of special order functions to support hybrid processes

- Post dispensing inspection function guarantees an ample dispensing effect (special orders)

- Dispense nozzle tip cleaning function (special order) prevents the dispense material from dripping during the production process.

- 3D mounting function (special order) is capable of dispensing and mounting onto 3D objects.

Reviews

There are no reviews yet.